The dewalt dw50, dw55, and dw1150 (and presumably more) machines have an enigmatic “special adjusting screw” with which you can adjust the height of the blades in the cutter block to the correct height.

The specs for these are not available anywhere on the internet. There are suppiliers that apparently sell them, but any of the items with images look at best marginally correct.

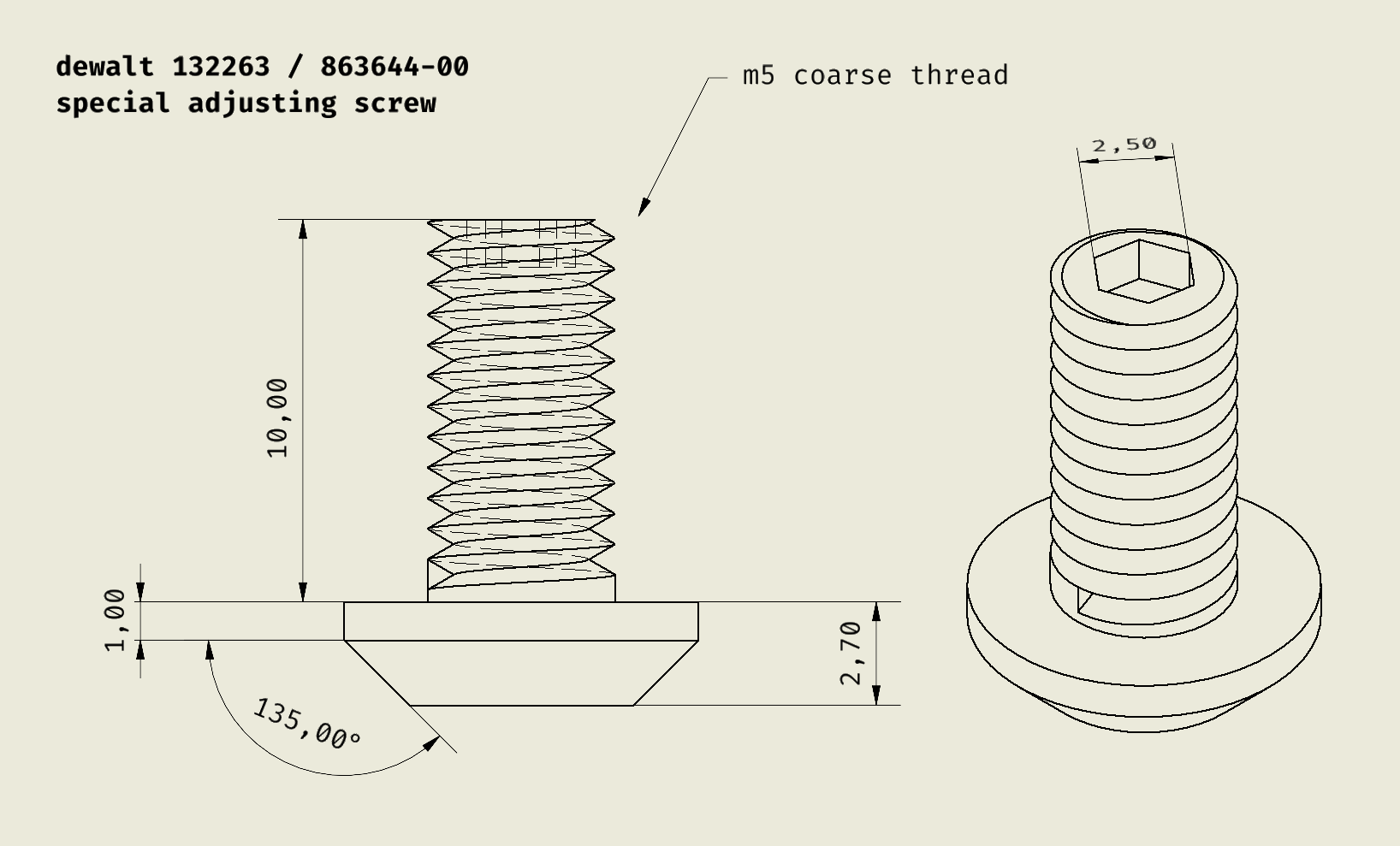

The screw, it seems, goes by different names and part numbers. I believe the actual canonical name to be

DeWalt 132263 special adjusting screw

It also goes by “black and decker” instead of dewalt (new parent company) and it also goes by part number 863644-00 if internet sources are to be believed.

I made four screws for my dw50 that work perfectly. Here is a mockup:

It is easily made by combining an m5 grub screw with a suitably thin / small disk.

I turned a 2.7mm x 8.75mm disc, drilled and tapped it for m5, and heavily chamfered the bottom with a 45degree tool for clearance of the shelf in the cutter block. I then welded this to an m5 grub screw. This allows for fine upward height adjustment of the cutter blades in the block for correct setting.

I think you could skip the chamfer if you used a thinner disk, but it can take considerable force to move the cutter against the friction of the blocking wedge.

You don’t need a lathe. Something good enough can be accomplished with a washer and basic tools like a file / epoxy and glue.

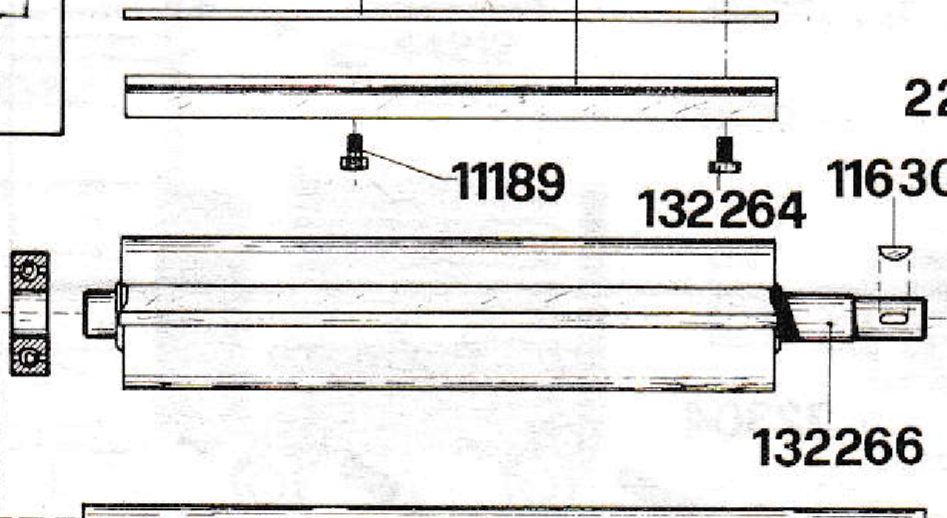

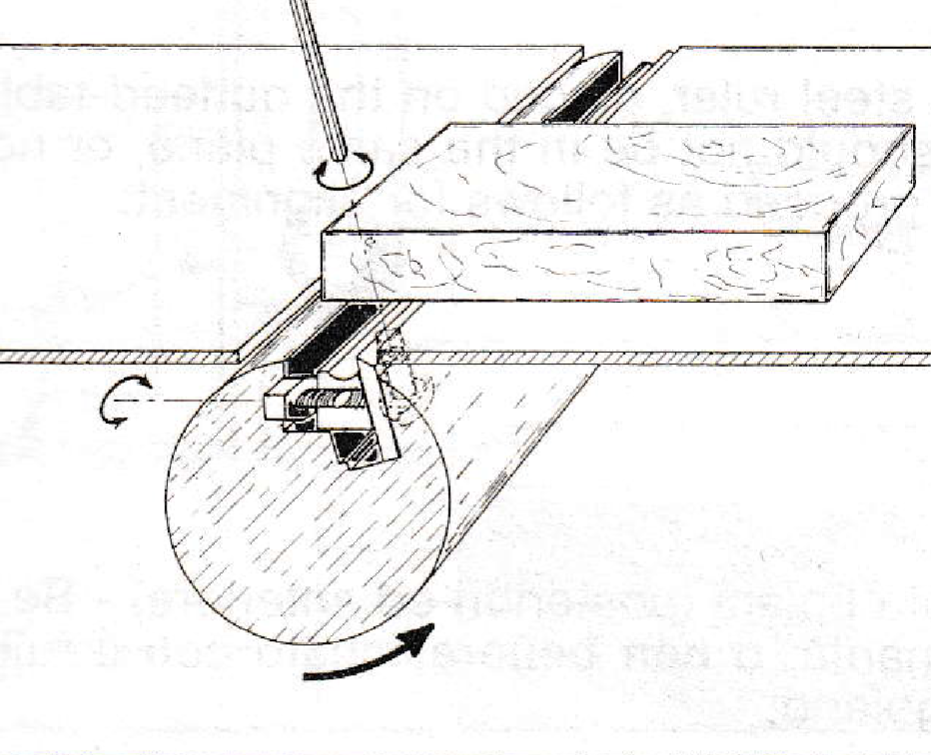

Below are images from the manual showing the “special screw” as part 132263 and showing the image where it discusses using them to adjust the blades - this image is terrible.

Suffice to say the “top” flat of the disk rides in the ground slot of the blade, lifting it as the grub screw is turned. The grub screw is screwed in from the bottom of the blocking wedge. It is driven from above through a hole in the wedge with a hex key - raising the blade.